The packaging film is wrapped around the product by the film conveying system. Then, the side edges of the film are sealed by the side-sealing device, forming a bag that encloses the product. After that, the product is conveyed to the heat shrink tunnel, where hot air shrinks the film and makes it fit tightly on the product surface, completing the packaging process.

- Film Conveying System: It consists of a film roll, a film tension control device and conveying rollers. It is used to place the packaging film and ensure the film maintains proper tension during conveying, so that it can be stably transported to the packaging position.

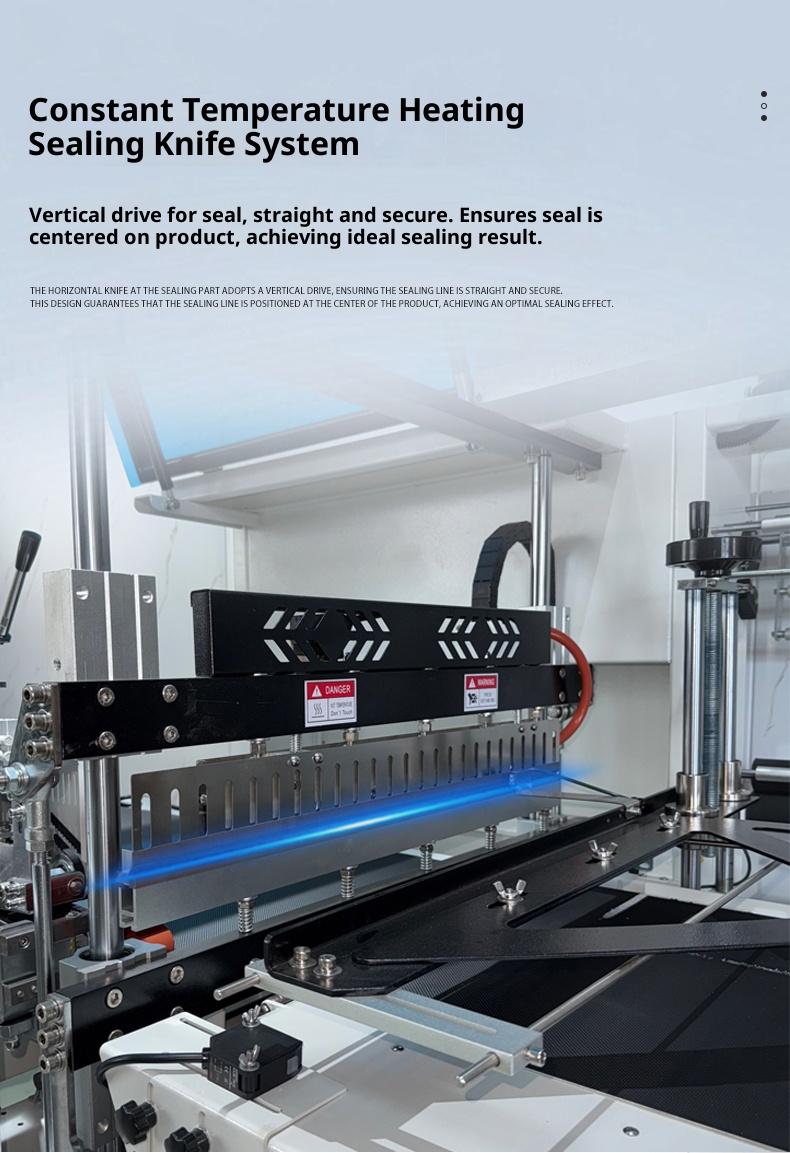

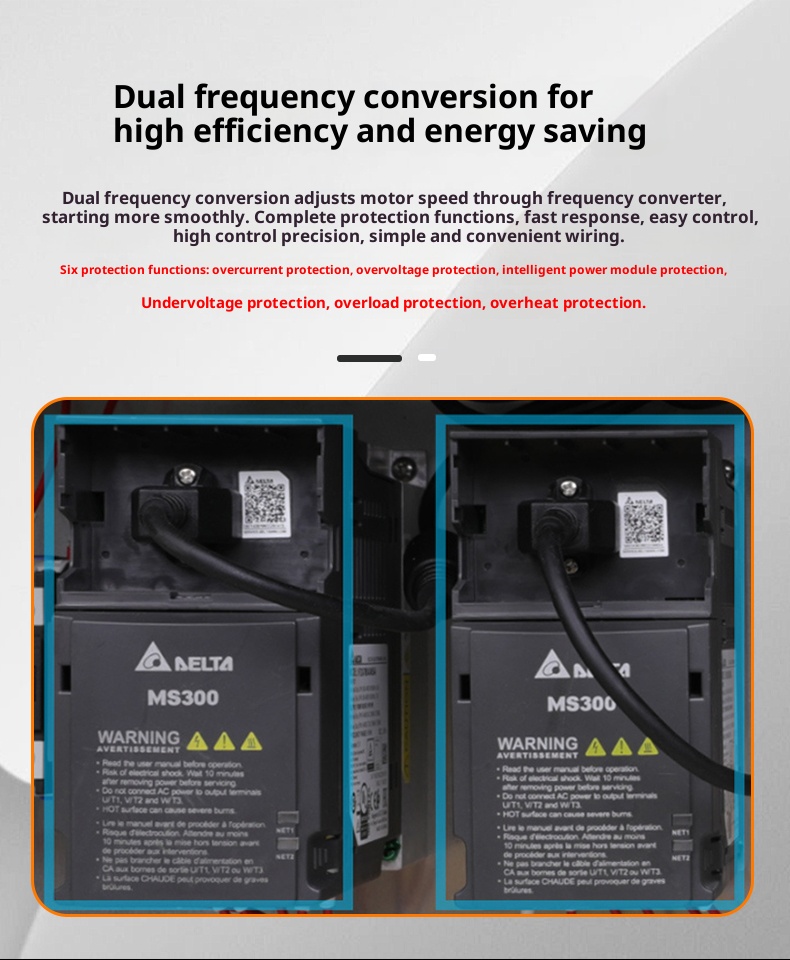

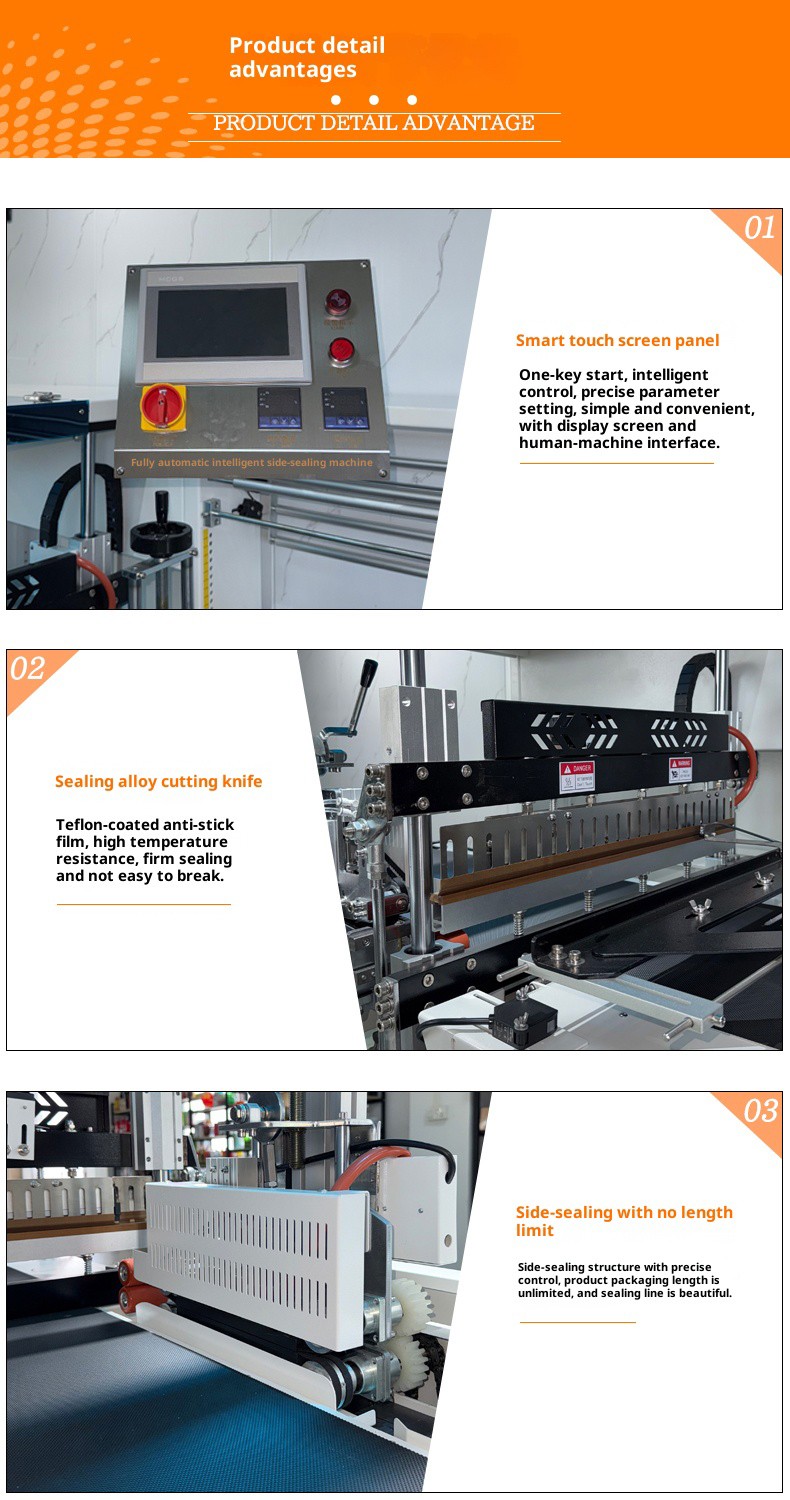

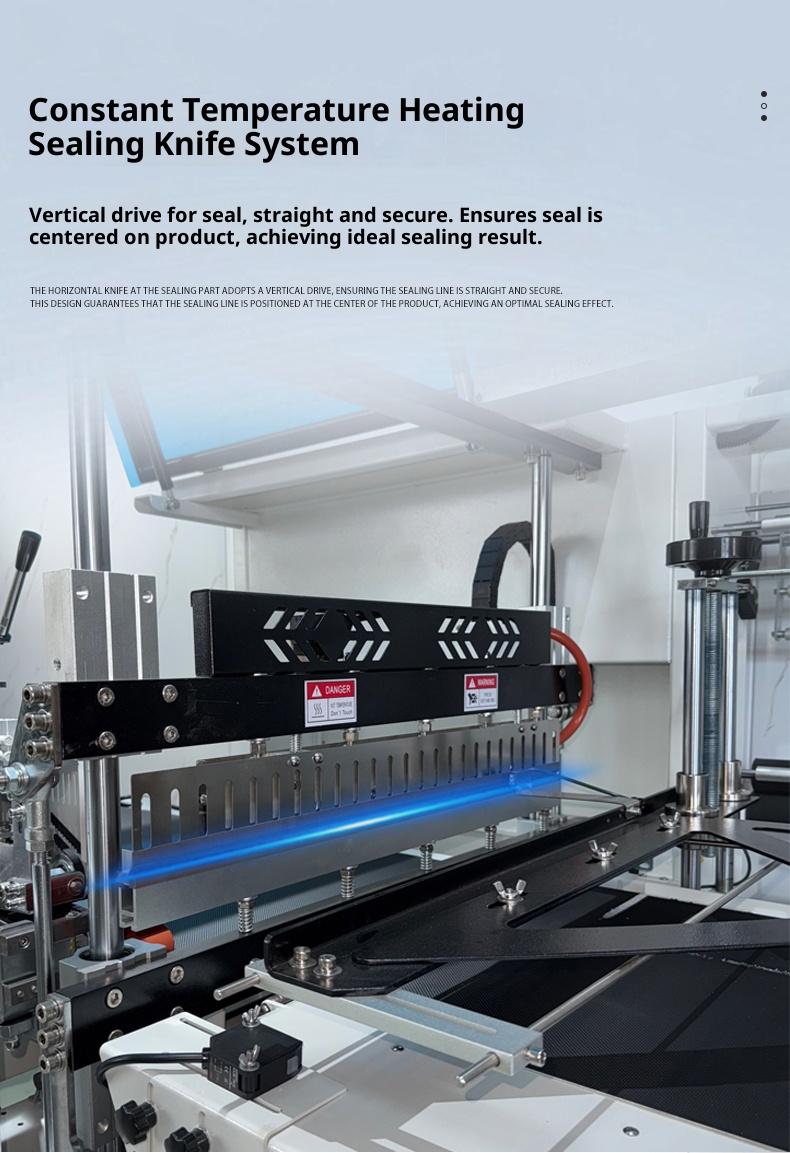

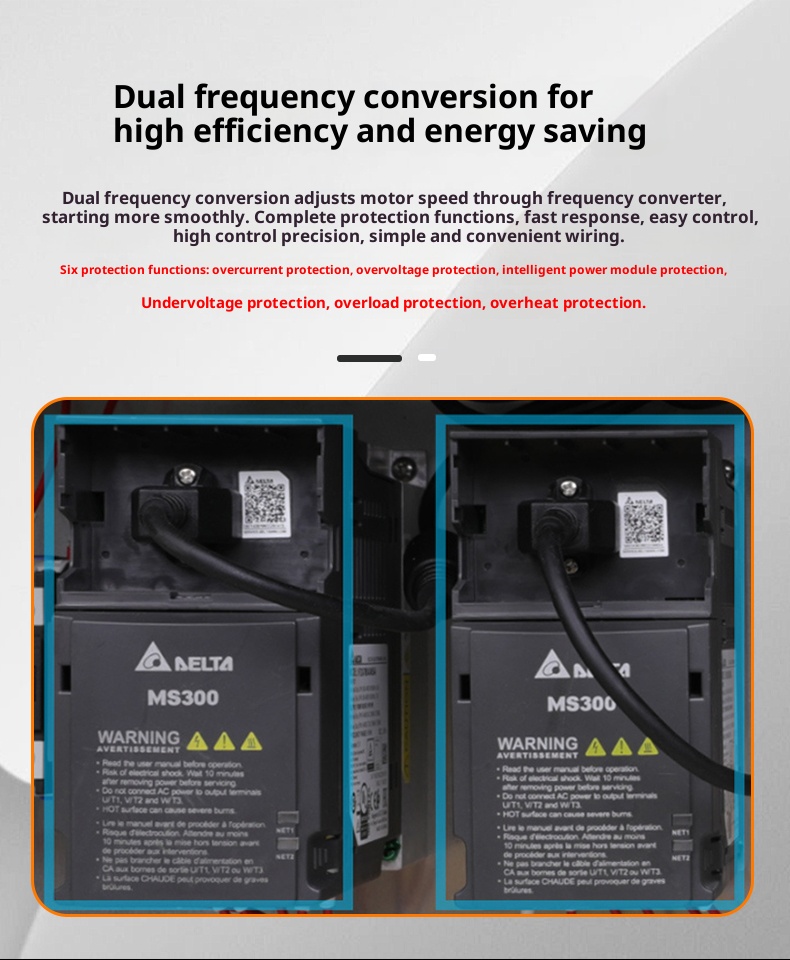

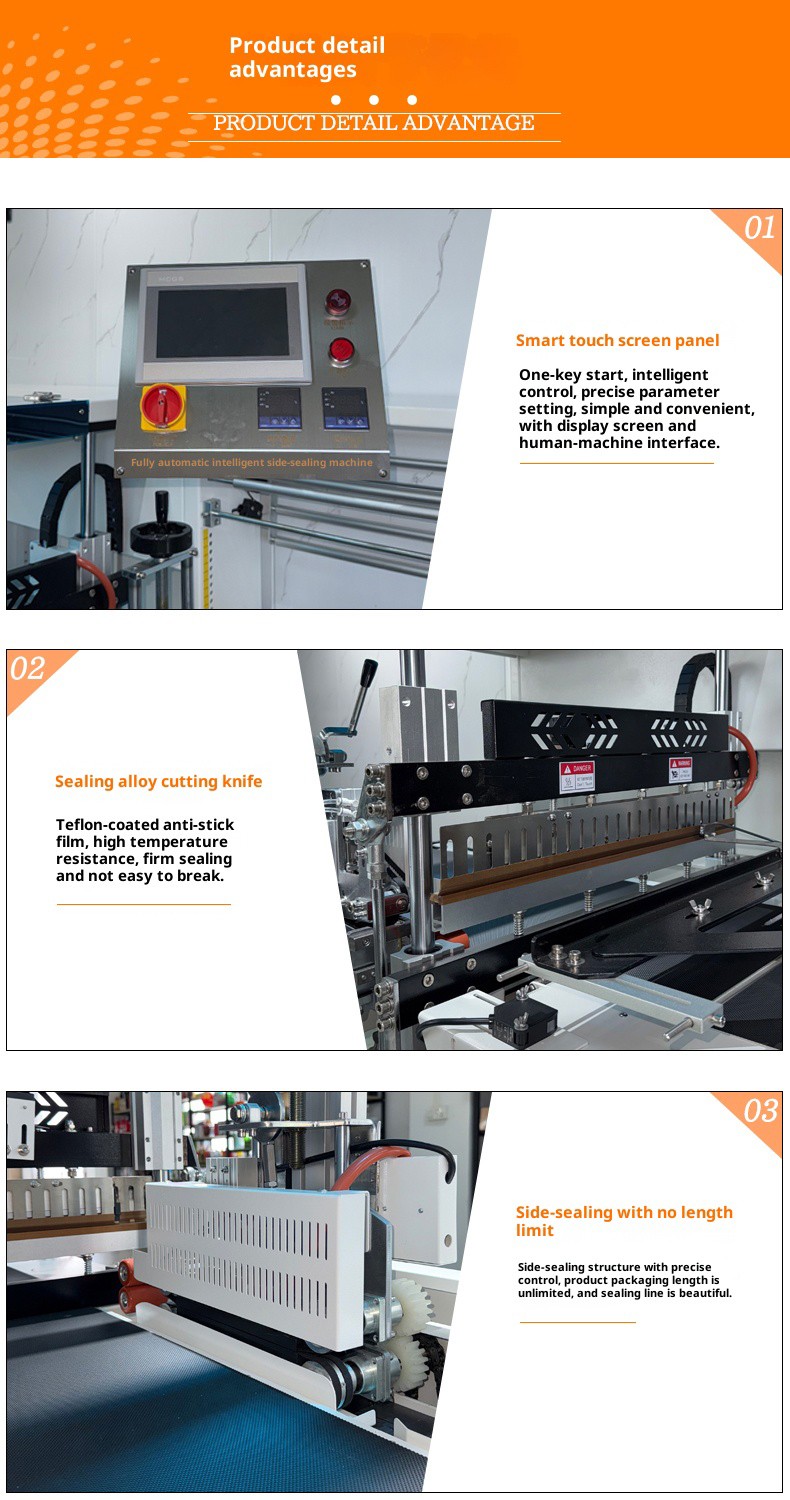

- Side-Sealing Device: Composed of a sealing knife, a heating element and a pressure adjustment mechanism. The sealing knife heats up under the action of the heating element, and squeezes the side edges of the film under the action of the pressure adjustment mechanism, making the side edges of the film melt and bond.

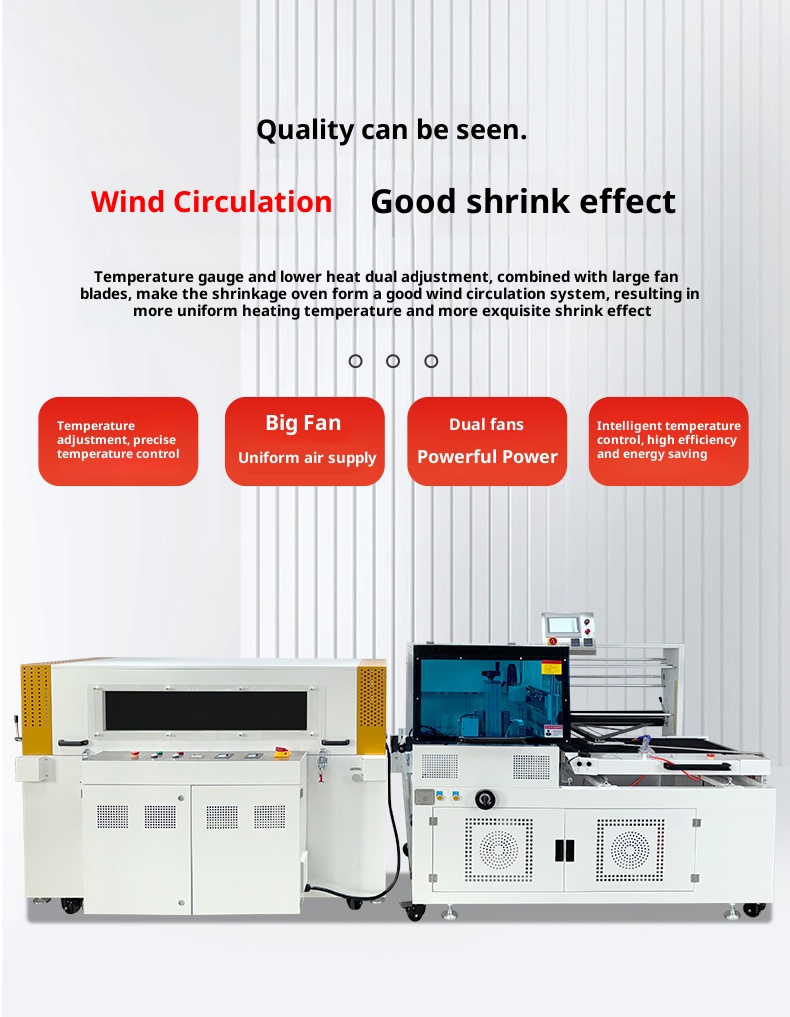

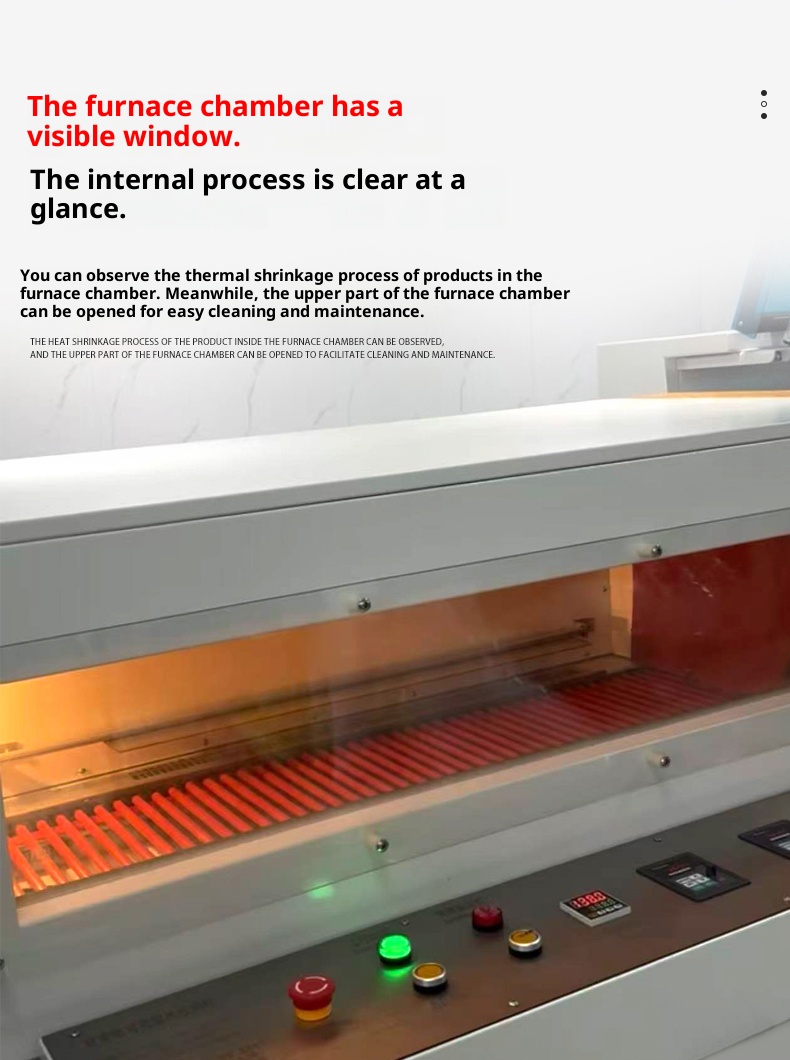

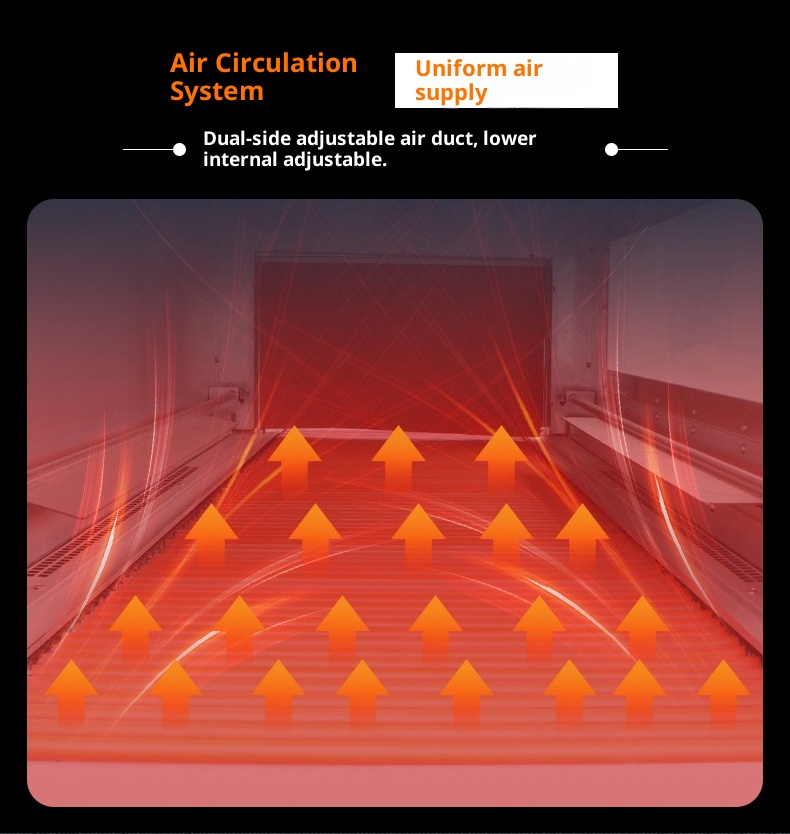

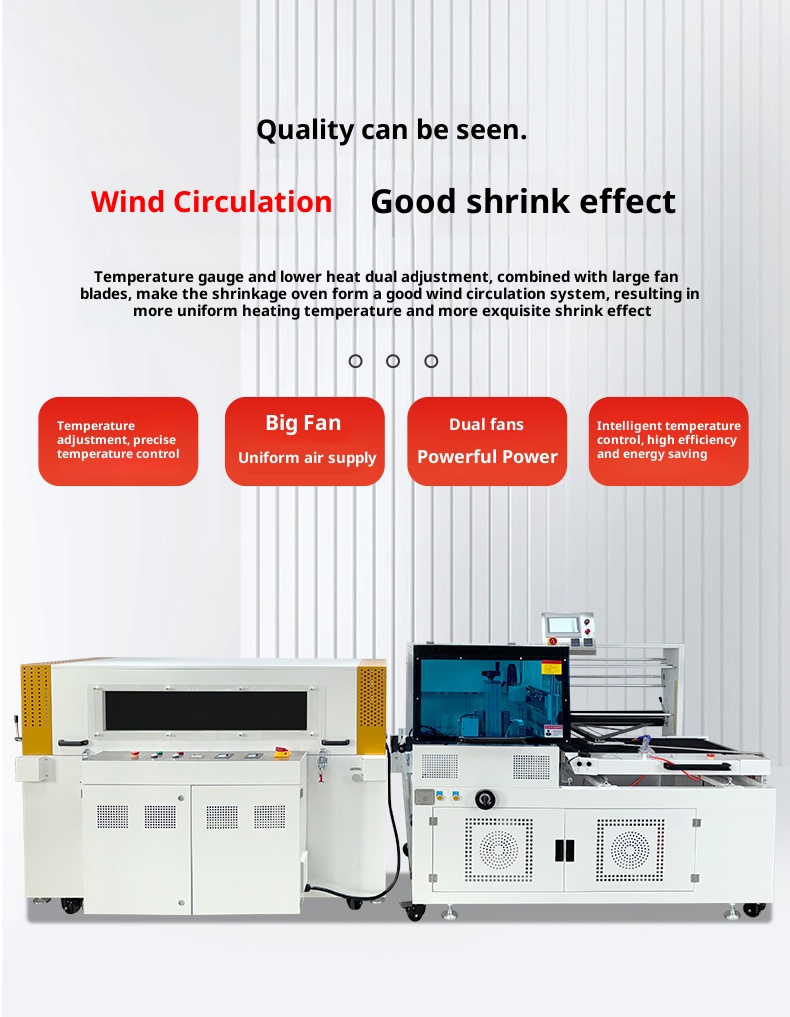

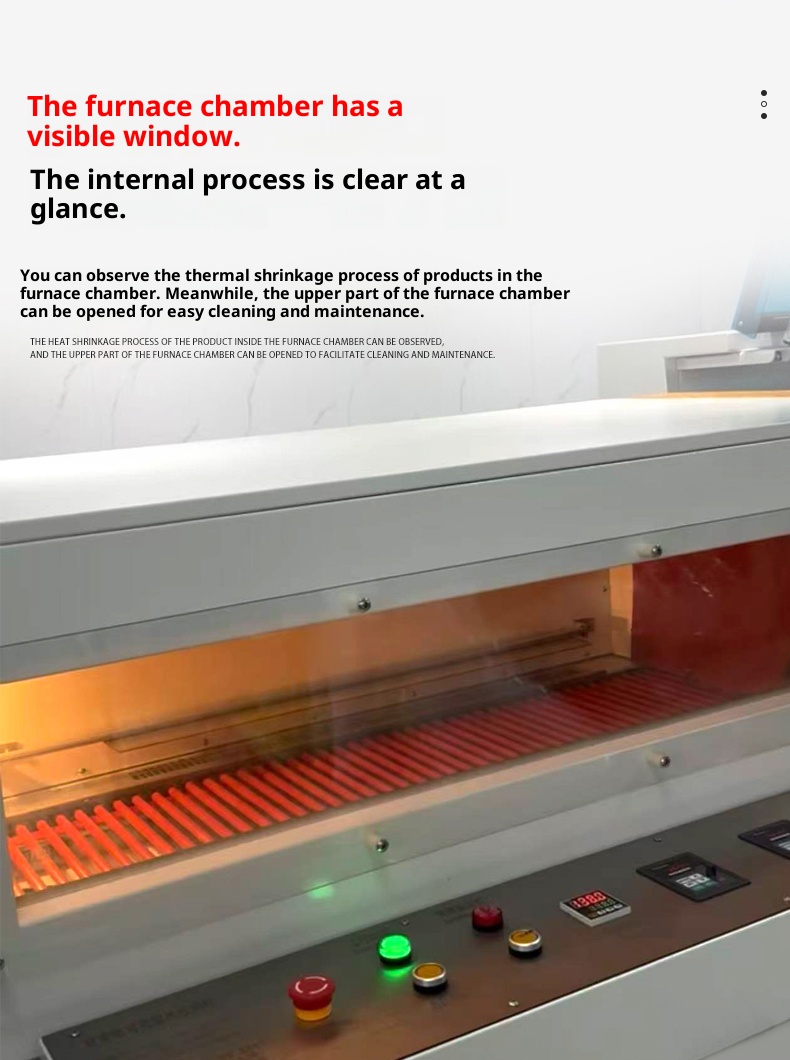

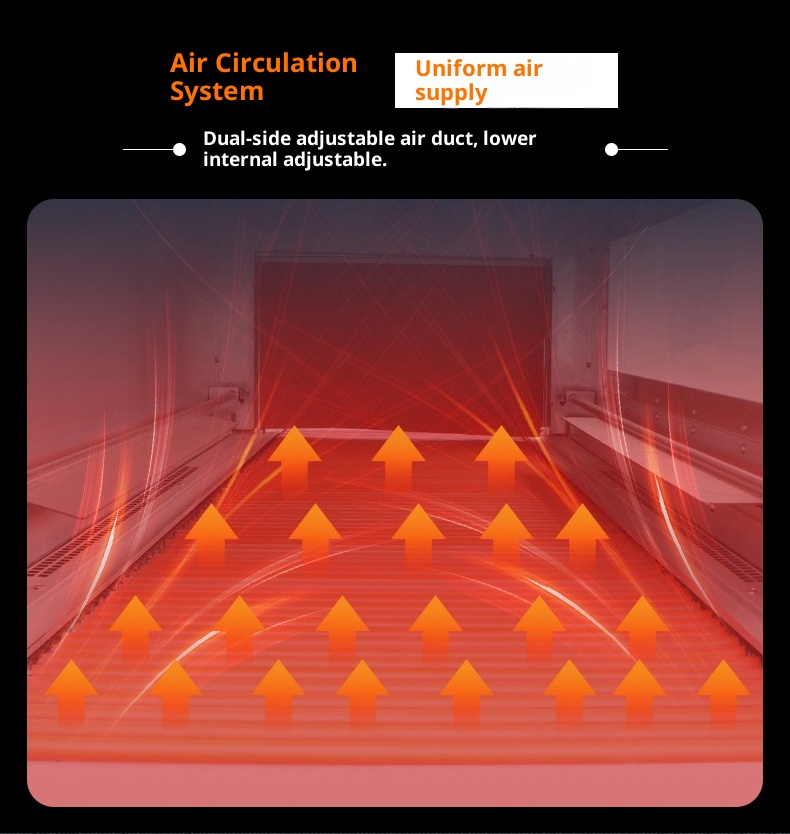

- Heat Shrink Tunnel: It is equipped with heating elements and ventilation devices inside. The heating elements generate hot air, and the ventilation devices distribute the hot air evenly, so that the film is heated and shrunk uniformly.

- Adjustable Packaging Specifications: For products with different packaging sizes, adjustment can be completed just by using a handwheel. Some machine models can also be adjusted automatically via a motor, featuring a wide range of applications.

- Good Sealing Quality: It adopts a constant-temperature alloy sealing knife with a Teflon non-stick coating on the surface. The seal will not be charred or produce smoke, and the sealing line is straight, firm, flat and neat.

- High Degree of Automation: It uses a PLC (Programmable Logic Controller) and is equipped with a photoelectric sensing device. It can automatically complete the whole process of conveying, sealing and heat shrinking. It can also be connected to a production line to realize unmanned production.

- High Production Efficiency: It has a fast packaging speed. Some high-speed models can achieve about 80 packages per minute and can work continuously, making it suitable for mass production.

- Good Safety Performance: It is equipped with safety protection and alarm devices. The cutting knife is equipped with a safety micro-sensing device, which can effectively prevent accidental cutting of products and ensure the safety of operators.